Products

Rim Straightening Machines

Products

RSM2400S-RSM2600S-RSM2800S

Rim Straightening Machine With Lathe

Rim Straightening Machine With Lathe

RSM2400S-RSM2600S-RSM2800S

Rim Straightening Machine With Lathe

Rim Straightening Machine With Lathe

Rim Straightening Machines

RSM Models / Rim Straighteners

Features

Specifications

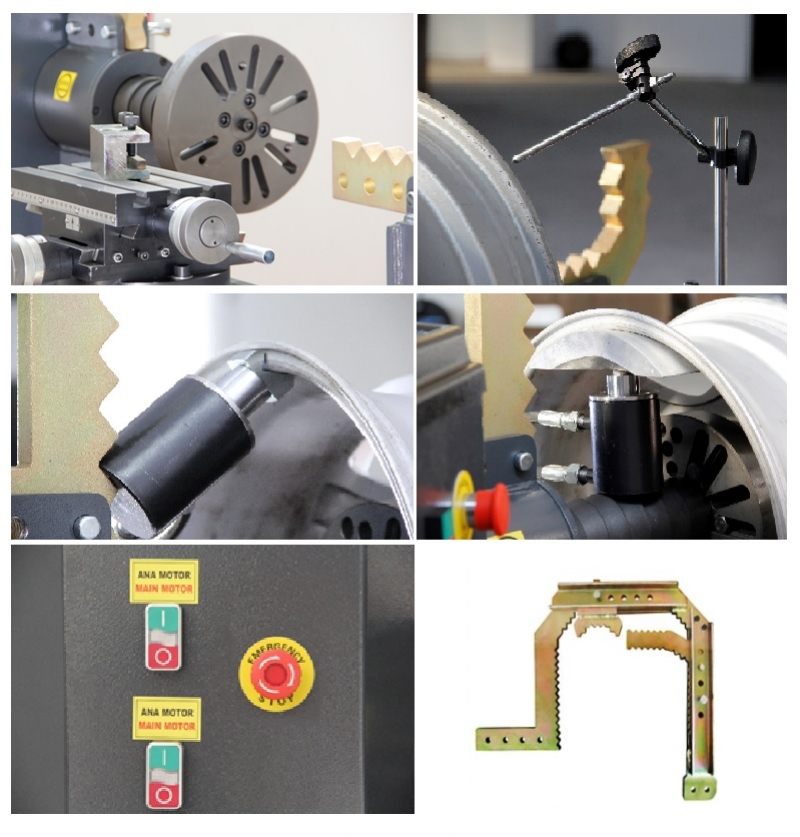

Detailed Image

RSM2400-S / RSM2600-S / RSM2800-S are all equipped with 5 ton power capacity of Hydraulic Pump, Molded flange, Small Lathe and necessary accessories/equipment to straighten defected rims made up of alloy, chrome, mag and sheet iron wheels from 10" to 28".

- Reliable Hydraulic system.

- High quality electric box and cabling.

- All parts have a 1-year warranty.

- Spare Parts support for 10 years.

- CE certified

| Model |

:

|

RSM2400-S / RSM2600-S / RSM2800-S |

| Capacity |

:

|

10”-24” / 10”-26” / 10”-28” |

| Mechanic Motor |

:

|

0,55Kw, 0,75Hp - 1400rpm - 7,3 Ampere |

| Hydraulic Motor |

:

|

0,55Kw, 0,75Hp - 1400rpm - 7,3 Ampere |

| Voltage |

:

|

220V/single Phase, 380V/3 Phase - 50/60Hz |

| Packing Dimensions |

:

|

800 x 1200 x 1520 / 1560 / 1600 mm |

| Weight Net/Gross |

:

|

280-300-320 / 320-340-360 kg |

| Sound Level |

:

|

35-40 db |

Standard Accessories

| 1. |

|

18 pcs Rim attaching center |

| 2. |

|

1 pc (mihengir) Metal pointer |

| 3. |

|

6 pcs Press tips (in different forms) |

| 4. |

|

3 pcs Support axis for press tips |

| 5. |

|

1 pc Lever |

| 6. |

|

1 pc Lathe pen |

| 7. |

|

1 pc Upper support |

| 8. |

|

1 pc Bottom support |

| 9. |

|

4 pcs Support pins |

| 10. |

|

1 set Flange nuts and bolts |

Rim Straightening Machines

RSM2200 HYDRO

Rim Straightening Machine

Rim Straightening Machine

RSM2200-RSM2400

Rim Straightening Machine with Lathe

Rim Straightening Machine with Lathe

RSM2400S-RSM2600S-RSM2800S

Rim Straightening Machine With Lathe

Rim Straightening Machine With Lathe

RSM1430-S

Rim Straightening Machine with Lathe

Rim Straightening Machine with Lathe

F.A.Q.

RSM2400MC-RSM2600MC-RSM2800MC

Moto Rim Straightening Machine

Moto Rim Straightening Machine

RSM2400-RSM2600-RSM2800

Chrome

Chrome

Rim Straightening & Polishing Machines

RSS2600-RSS2800

Rim Straightening & Polishing Machine

Rim Straightening & Polishing Machine

RSS1430

Rim Straightening & Polishing Machine

Rim Straightening & Polishing Machine

Rim Polishing Machines

RPM3200

Rim Polishing Machine

Rim Polishing Machine

RPM3200-S

Rim Polishing Machine

Rim Polishing Machine

Tyre Changers Light Duty

LST26-S

Automatic Tyre Changer

Automatic Tyre Changer

ANATOLIO TTC26

Automatic Tyre Changer

Automatic Tyre Changer

ANATOLIO TTC26-II

Automatic Tyre Changer

Automatic Tyre Changer

ANATOLIO TTC806

Motorcycle Tyre Changer

Motorcycle Tyre Changer

LC885A

Super Automatic Tyre Changer

Super Automatic Tyre Changer

Tyre Changer Heavy Duty

LEON2800-S

Truck Tyre Changer

Truck Tyre Changer

LEON5600S

Heavy Duty Tyre Changer

Heavy Duty Tyre Changer

Vehicle Lifts

EPL3000

PNEUMATIC FLOOR PLATFORM

PNEUMATIC FLOOR PLATFORM

ZTM-SL3200

FULL RISE SCISSORS LIFT

FULL RISE SCISSORS LIFT

ZTM-40FP

ZTM-50CE

TDY-P3010

MID-RISE SCISSORS LIFT

MID-RISE SCISSORS LIFT

Wheel Balancers

MB-200

Mobile Finish Balancer

Mobile Finish Balancer

Automatic Wheel Balancer

3D Wheel Alignment

TECHNO VECTOR WHEEL ALIGNER

Contacts

| ZETAB MAKINA SANAYI VE TICARET LTD. STI. Kemalpasa OSB Mah. 602 Sokak No.1 35730 Kemalpasa IZMIR / TURKIYE |

|

| Phone : | +90 232 445 9445 |

| Cell : | +90 543 445 0812 |

| Fax : | +90 232 445 0812 |

| Email : | zetamak@zetamak.com |